Elon Musk's Optimus: Tesla's Bold Bet on Humanoid Robots

Elon Musk's Optimus: Tesla's Bold Bet on Humanoid Robots

Tesla's Strategic Vision for Humanoid Robotics

Tesla has identified humanoid robotics as a central element of its long-term strategy, extending beyond its core electric vehicle business. The company is developing Optimus, a general-purpose humanoid robot intended to operate in environments designed for humans, including factories, offices, homes, and potentially medical and space applications. Elon Musk has stated that Optimus could become a major revenue contributor for Tesla over time, positioning robotics as a future growth engine rather than a peripheral research effort.

Invest in top private AI companies before IPO, via a Swiss platform:

Industry analysts often compare this strategic shift to historical platform expansions in technology, where an initial product category enabled capabilities that later supported broader markets. In this context, Tesla’s electric vehicles are frequently described as advanced autonomous systems that have allowed the company to build expertise in artificial intelligence, sensors, and large-scale manufacturing. Tesla’s long-term objective is to apply these capabilities to robotics, potentially opening a new category of physical automation.

This strategic emphasis has gained prominence as competition in the global electric vehicle market has intensified and growth rates have moderated. Investor attention has increasingly shifted toward Tesla’s non-automotive initiatives, including autonomous driving, robotaxis, and humanoid robotics.

Technical Architecture and Design Philosophy

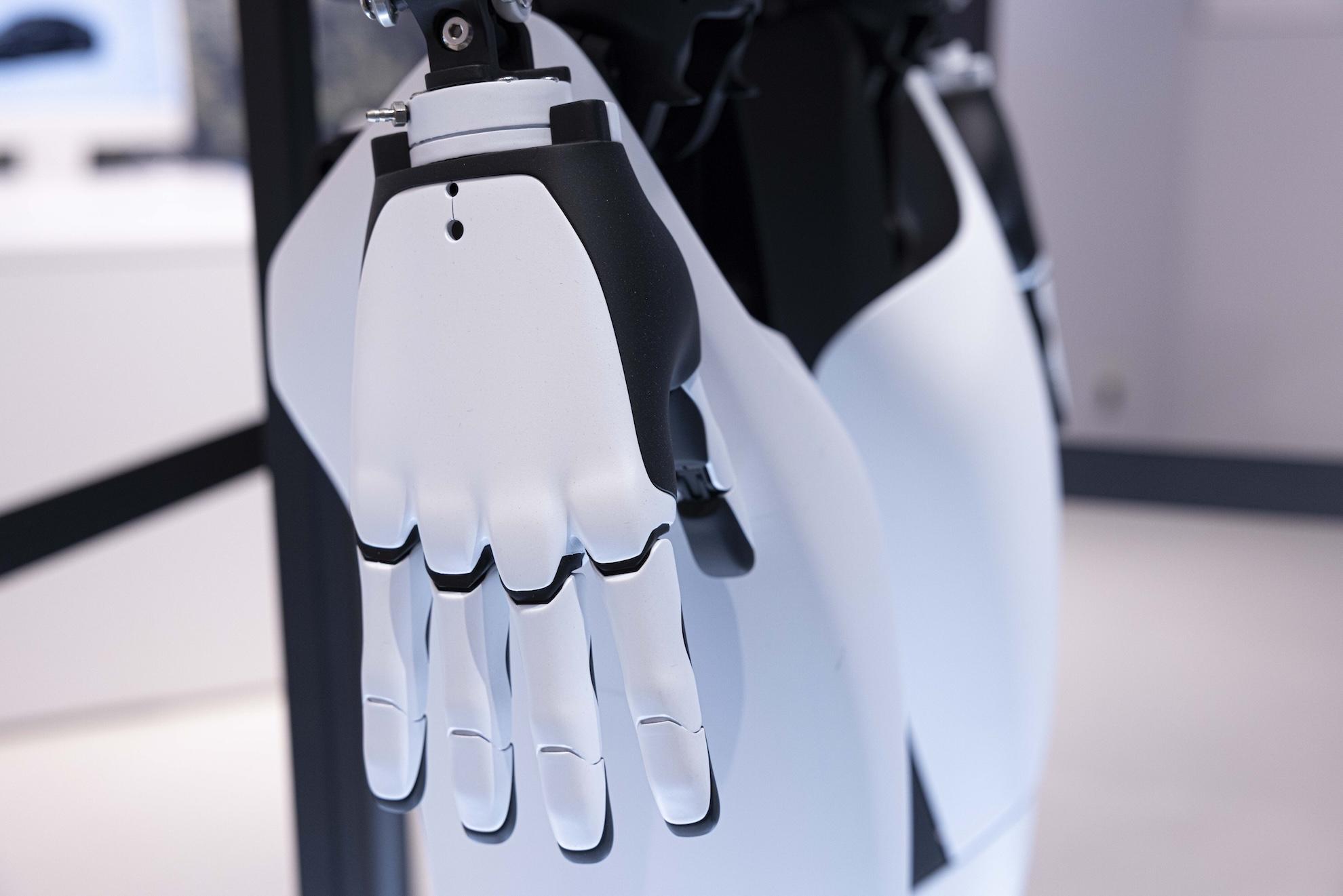

Optimus is designed as a bipedal humanoid robot, approximately human-sized, with articulated joints, hands, and vision systems intended to function in existing human environments. Traditional industrial robots typically operate as fixed systems optimized for narrowly defined tasks. While highly efficient, they require structured environments and lack adaptability.

Tesla’s approach prioritizes flexibility over specialization. The humanoid form factor is intended to allow Optimus to use existing tools, navigate stairs and doorways, and operate in spaces not purpose-built for automation. This design choice aims to reduce the need for costly infrastructure changes, which often slow automation adoption.

The underlying assumption is that a general-purpose robot capable of adapting to varied tasks could provide broader economic value than task-specific machines. However, this approach also introduces substantial technical complexity, particularly in mobility, balance, safety, and energy efficiency.

Development Evolution and Public Demonstrations

Optimus has progressed from early conceptual prototypes to functional machines capable of basic movement and object manipulation. Tesla has demonstrated robots navigating office environments, performing simple tasks such as sorting objects, carrying items, and operating tools under controlled conditions.

Public demonstrations have included staged presentations and event appearances, some of which have relied on teleoperation, where human operators control the robot remotely. Tesla has acknowledged that teleoperation remains part of the development process, particularly for training and safety validation. These demonstrations provide visibility but do not yet represent fully autonomous operation.

Internally, Optimus units are reportedly used for experimentation and training within Tesla facilities. These deployments are focused on gathering data, improving perception systems, and refining motion control rather than replacing human labor at scale.

Learning Methodology and Artificial Intelligence Integration

Tesla applies a learning approach similar to its autonomous driving program. Optimus relies primarily on vision-based perception, neural networks, and data-driven training rather than pre-programmed behavior. The robot is trained using large volumes of real-world data, including recordings of human movement and task execution.

Training includes imitation learning, where the robot observes and learns from human demonstrations, as well as reinforcement learning in structured environments. Tesla employees collect motion and interaction data using wearable sensors and cameras, allowing Optimus to model how humans navigate spaces and manipulate objects.

The objective is to enable Optimus to generalize from observed behavior and adapt to new environments. This approach emphasizes scalability but requires extensive data, computational resources, and iterative refinement.

Technical Challenges and Engineering Obstacles

Despite visible progress, humanoid robotics remains one of the most technically demanding areas of artificial intelligence and engineering. Key challenges include perception accuracy, real-time decision-making, and fine motor control.

Hand dexterity is a critical limitation. Many everyday tasks require nuanced grip control, force adjustment, and tactile feedback that remain difficult to replicate mechanically. Errors in grip strength or positioning can lead to dropped objects or damage, particularly in unstructured environments.

Mobility and balance present additional challenges. Bipedal locomotion requires continuous stabilization and rapid adjustment to external forces. Power efficiency and fail-safe behavior are also major considerations, especially in environments shared with humans.

Experts note that even minor improvements in reliability and autonomy require substantial engineering effort, making the path to large-scale deployment uncertain.

Design Philosophy Debates and Alternative Approaches

The humanoid form factor remains a subject of debate within the robotics industry. Some companies prioritize wheeled or fixed platforms, citing improved stability, lower cost, and higher reliability for many industrial applications.

Critics argue that general-purpose humanoid robots may be less efficient than specialized machines for well-defined tasks. Wheeled robots, for example, require less energy for movement and pose fewer safety risks in the event of power loss.

Tesla’s decision to pursue a humanoid design reflects a long-term perspective rather than short-term optimization. The company is effectively prioritizing versatility over immediate efficiency, a choice that increases both potential rewards and technical risk.

Market Applications and Economic Implications

Potential applications for humanoid robots span manufacturing, logistics, healthcare support, household assistance, and hazardous environments. In the near term, deployment is most likely in controlled settings where tasks are repetitive but require flexibility, such as material handling or equipment monitoring.

Consumer applications remain speculative. While household assistance represents a large theoretical market, safety, reliability, cost, and regulatory considerations are significant barriers. Aging populations and labor shortages may increase demand for robotic assistance over time, but adoption timelines remain uncertain.

Long-term projections for humanoid robotics vary widely. Some analysts estimate multi-trillion-dollar global markets by mid-century, though such forecasts depend on breakthroughs in autonomy, cost reduction, and social acceptance.

Current Status and Development Timeline

Optimus is currently in an advanced prototype stage. Tesla is reportedly working on multiple hardware and software iterations, with each generation improving mobility, perception, and manipulation capabilities.

Initial timelines suggesting near-term deployment in Tesla factories have been adjusted as technical challenges emerged. Current development efforts focus on incremental autonomy gains rather than immediate commercial rollout.

While progress is ongoing, the gap between prototype performance and reliable, unsupervised operation remains significant.

Competitive Landscape and Industry Development

Tesla operates within a rapidly expanding humanoid robotics ecosystem. Competitors include startups such as Figure and 1X, established robotics firms like Boston Dynamics, and several Chinese manufacturers leveraging large-scale production capabilities.

Each competitor emphasizes different priorities, ranging from industrial reliability to cost optimization or consumer-focused design. No single approach has yet emerged as dominant, and multiple architectures may coexist across applications.

Competition is likely to accelerate innovation but also increase pressure to demonstrate practical value beyond demonstrations.

Financial Implications and Investment Considerations

Optimus represents a long-duration investment with uncertain timelines and outcomes. Tesla’s leadership has linked executive compensation and long-term valuation targets to success in autonomous systems and robotics, aligning management incentives with this strategy.

For investors, Optimus is generally viewed as an option on future technological breakthroughs rather than a near-term revenue driver. Most financial models exclude meaningful robotics revenue in current projections due to uncertainty around commercialization.

The upside potential is substantial, but execution risk remains high. The success or failure of Optimus will significantly influence Tesla’s long-term identity as either a diversified technology company or a primarily automotive manufacturer.

The Path Forward

Tesla’s humanoid robotics program reflects a broader ambition to decouple physical labor from human availability. Achieving this objective requires sustained advances in artificial intelligence, mechanical engineering, and systems integration.

Near-term progress will likely be measured in incremental autonomy improvements and limited deployments rather than large-scale labor replacement. The long-term outcome depends on whether general-purpose humanoid robots can achieve sufficient reliability, safety, and cost efficiency.

Optimus remains central to Tesla’s long-term narrative. Whether it becomes a transformative commercial product or remains a prolonged research initiative will shape not only Tesla’s future, but also broader expectations for humanoid robotics in the global economy.